Lead Free Turning in highest Precision

Achieving lead free turning through extreme rigidity

The bearing and sealing diameters of shafts, axles or gears, have the highest requirements for accuracy and surface finish. For a long lasting function of seals and bearings the requirements for these diameters are lead free and high surface finish.

Since these surfaces are usually hardened for a high wear resistance, it makes it even more challenging to machine these features.

In the past such surfaces were machined with ID or OD grinding on separate machines. Driven by cost effectiveness and flexibility, the classic grinding process with cutting fluid was substituted by lead free hard turning. For this application various most very complex processes were developed, which create a skiving motion with additional axes moving in a relative motion.

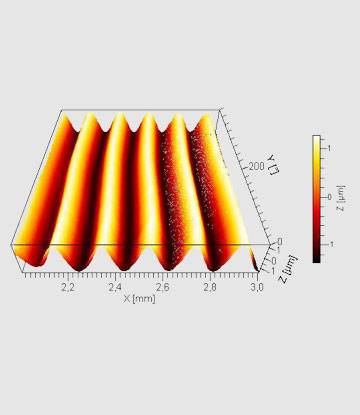

The Felsomat modified grooving process, which achieves an absolute lead free surface by an incremental Z axis feed, gives the highest accuracy and cost effectiveness to the customer. With the axial feed and the different insert tip radius, it is possible to create almost any surface finish requirements specified. The requirement for achieving such results is an extremely rigid machine, which is the trademark of all Felsomat turning centers.