From Rough Part to the finished Valve Body

Premium Technologies and Automation extend

In an automatic car transmission the valve body is one of the key functioning components. The work pieces can be unstable, based on labyrinth style geometry, but because of the function of controlling the valves for the gear shifting of the automatic transmission it also has tight tolerances to machine. The tolerances have a direct impact on shifting. Too large of a tolerance is resulting in slow and / or jerky shifting.

Often the valve bodies are clamped on adapter plates to reduce the impact of dirt and chips during the machining process on the locating and clamping faces. The adapter plate is the common interface between the work piece and the clamping fixture of the machine. The assembly between adapter plate and work piece is done outside the machines in the Felsomat logistics module. The assembly is done with electro mechanic bolt stations in highest reproducible quality. The positioning of the bolt units is done with NC controlled servo axes. The control of the required torque and rotation angle of the bolting process is included as well as the sensing of the part location. The swivel clamps are hooked up to a central lubrication system. Inaccuracy in the bolting process has a direct negative impact on the machining result. The automation specialist has to guarantee the absolute distortion free clamping of the valve body to the adapter plate.

Before the assembly can be done a careful cleaning of the valve body is required to avoid any influence of chips or dirt from the upstream operation.

The big advantage of the adapter plate in general is, that there is no additional adaption of the machine tool or the automation required to clamp or grip a variety of different work pieces bolted to the adapter plate. If during the life cycle of a product additional work pieces are added to the product mix, all that is required are additional adapter plates, giving the whole system highest flexibility at highest quality requirements. RFID tags attached to the adapter plate allow for seamless part tracking.

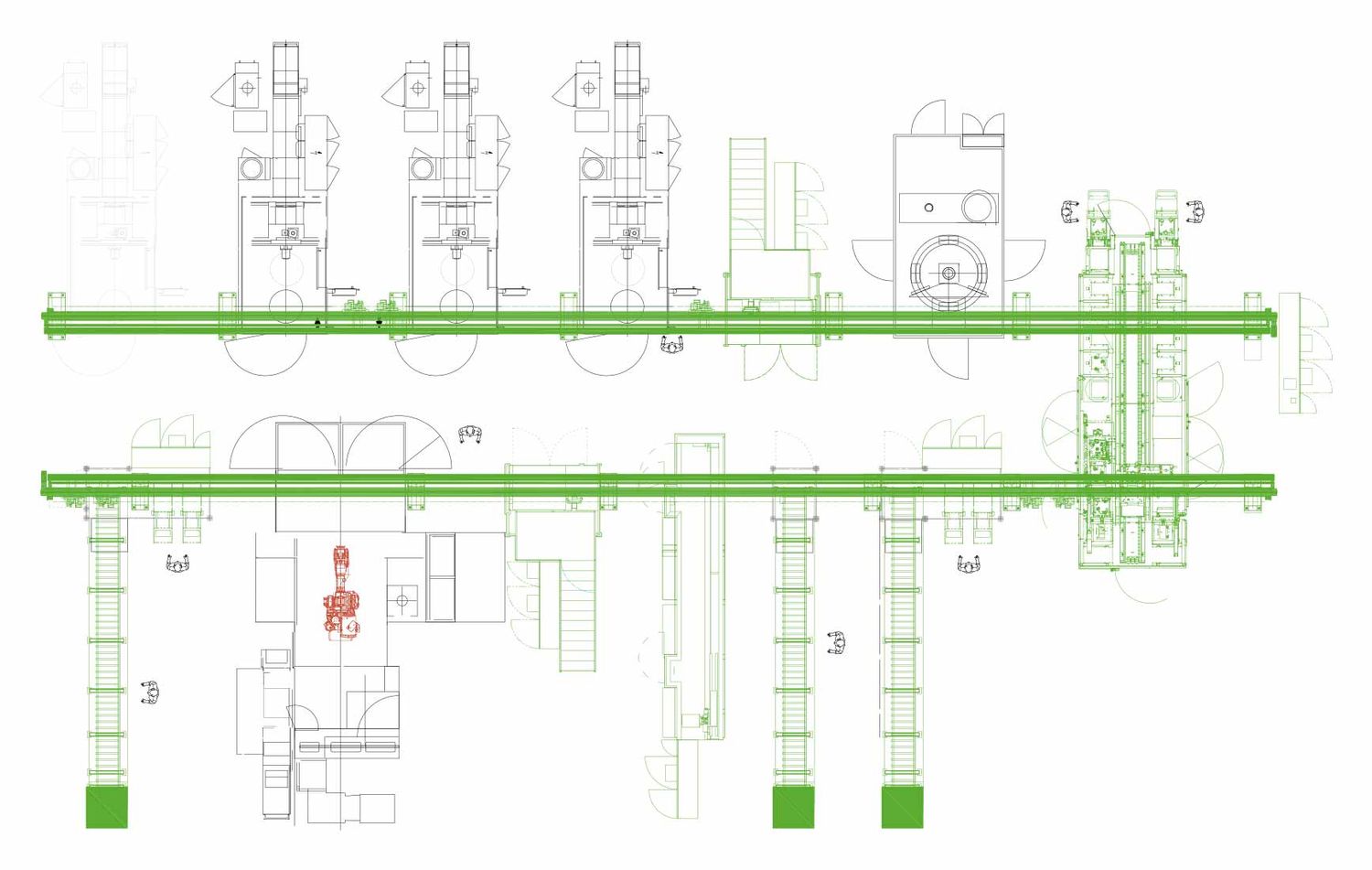

The Felsomat universal and modular automation building blocks, as well as the strong experience in numerous projects, are the ideal qualification for the customer requirements:

- Storage of adapter plates inside the logistics module

- Assembly (mating) of work piece and adapter plate

- Bolting, control of rotation angle and torque

- Cleaning / blow off of work piece and adapter plate

- Univeral interface of the adapter plate for the machine tool and automation

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/3/csm_amb_2445a99f0d.jpg)