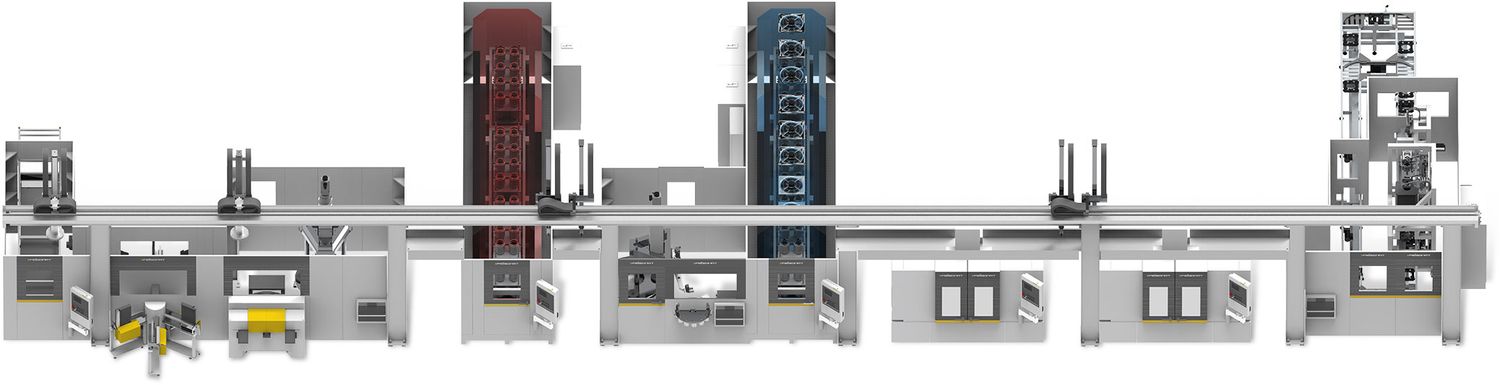

Rotor assembly

The magnets are delivered with an anti-twist device and set into the rotor lamination at the setting station. The rotor lamination is lifted and rotated during the setting procedure.

Magnets are secured to the lamination stack by coating them with plastics or by bonding them with a glue or special bonding agent.

The rotor laminated stack is joined and the bolted together with screws.

The rotor lamination assembly is heated homogeneously and brought to a set temperature.

The rotor shaft is set into the rotor lamination stack using a delivery unit and then joined.

The assembled rotor is then checked for balance and, if needed, a material removing process like boring is used to balance the assembly.

The internal magnets in the rotor laminations are magnetized using a coil with integrated measurement and control.

The finished rotor assembly is measured in-line for overall magnetic flux using a magnetometer.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/3/csm_amb_2445a99f0d.jpg)